Upgrading an industrial air system requires thoughtful planning and an understanding of how compressed air affects daily operations. An air line upgrade is not just a replacement of pipes or fittings. It is a structural improvement that impacts productivity, energy efficiency, equipment lifespan, and workplace safety. Facilities that rely heavily on pneumatic tools, automation, or high-volume production benefit significantly from asking the right questions before starting an upgrade.

Modern operations demand stable air pressure, clean airflow, and efficient distribution systems. When existing lines begin to show signs of wear or when production needs increase, an air line upgrade becomes essential. However, the decision should be made with clear insight into system capacity, layout design, future expansion, and compliance requirements.

Addressing these factors before upgrading ensures that the new system performs reliably and supports the long-term needs of the facility.

Is Your Current System Showing Signs of Decline?

Before investing in an air line upgrade, the first step is to evaluate whether the current system can still meet operational demands. Subtle signs of decline often appear months before noticeable performance failures occur.

Key indicators that suggest system decline include:

- Pressure drops during peak usage periods

- Visible corrosion or damaged fittings along the air lines

- Increased energy use due to compressor strain

Pressure inconsistencies are often the earliest signal of a failing system. When lines are clogged, corroded, or leaking, compressors must work harder to maintain adequate airflow. This increases operational costs and accelerates equipment wear.

Corrosion is especially concerning because it can lead to sudden line failure. Damaged fittings may appear harmless, but can create small leaks that grow over time. Expert guidance on air line replacement signs provides further clarity on when declining systems need evaluation.

If multiple symptoms appear simultaneously, an upgrade becomes more urgent. Understanding these signals helps prevent unplanned downtime and ensures the new system is designed to correct existing weaknesses.

What Capacity and Pressure Requirements Will Future Operations Demand?

Many facilities upgrade their air lines only to discover later that their new systems lack the capacity needed for expanding operations. Before deciding on an air line upgrade, evaluating current and anticipated air demand is crucial.

Consideration should be given to:

- The number of pneumatic tools or machines operating simultaneously

- Peak pressure requirements during production cycles

- Planned expansions or new automated processes

Every piece of air-powered equipment has a specific cubic feet per minute requirement. When multiple tools operate at the same time, the air system must deliver steady pressure without fluctuation. Undersized lines or outdated compressors can cause interruptions that slow production.

Future planning is equally important. If the facility expects to incorporate robotics, add new workstations, or expand into additional warehouse space, the upgraded system should be designed with adequate overhead.

A well-sized air line system avoids pressure drops, protects machinery from strain, and ensures long-term operational reliability.

Are You Choosing the Right Materials and Layout for Your Facility?

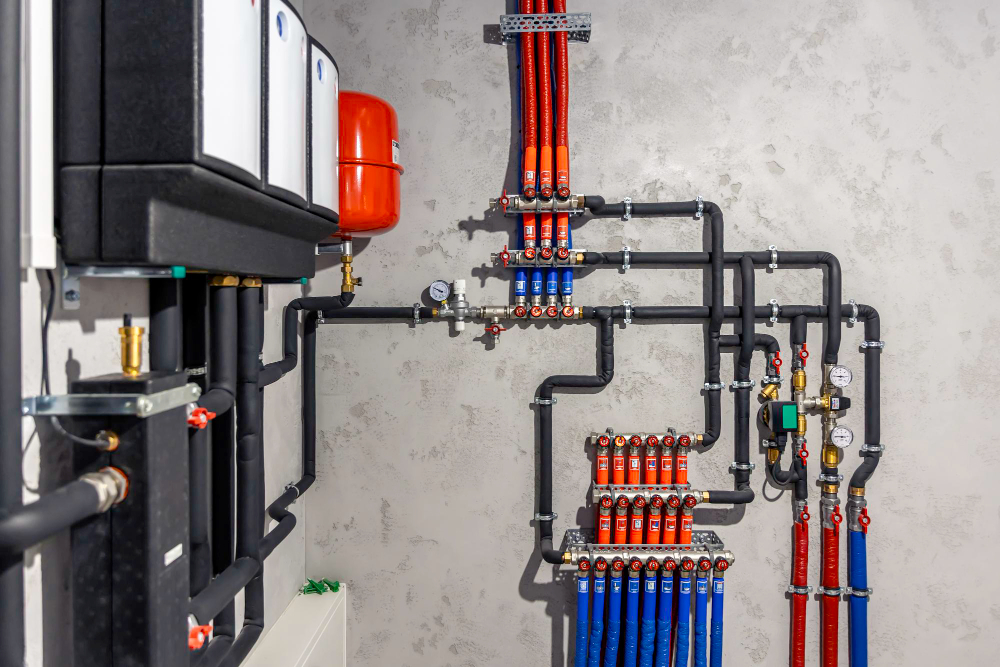

Not all compressed air materials are suited for all environments. The choice of pipe material, line diameter, and layout design significantly impacts the performance and lifespan of an air line upgrade.

Material and layout considerations include:

- Selecting pipe materials resistant to corrosion and pressure fluctuations

- Designing a loop or branch system that supports balanced air distribution

- Ensuring proper placement of drains, filters, and shutoff valves

Industrial environments vary greatly. Some facilities experience high humidity, which increases the risk of internal rusting. Others require tight pressure control for sensitive equipment used in assembly, packaging, or finishing tasks.

The layout of the system influences energy efficiency and overall output. Loop systems often provide more consistent pressure compared to straight branch lines, making them ideal for large production floors. Strategic placement of filtration eliminates moisture and debris that could damage pneumatic tools.

Warehouse and production environments benefit from designs modeled after proven industrial air solutions to maximize performance and safety.

Choosing the right materials and system layout is foundational to a successful air line upgrade.

How Will You Manage Moisture, Filtration, and Air Quality?

Compressed air naturally contains moisture, oil particles, and airborne contaminants. An effective air line upgrade must include filtration and moisture management systems that protect both equipment and finished products.

Essential air quality considerations include:

- Properly sized filters that remove dust, oil aerosols, and particulates

- Moisture traps placed at strategic points to prevent water buildup

- Drainage systems that automatically remove accumulated condensation

Moisture is one of the leading causes of damage in pneumatic equipment. When water collects in air lines, it corrodes metal pipes, damages seals, and reduces tool efficiency. Moisture also affects the consistency of spray equipment and sensitive manufacturing processes.

Selecting the correct filtration system requires understanding the specific needs of the facility. Tools that require ultra-clean air need different filters than heavy-duty machinery.

High-quality air ensures consistent production, protects investments, and reduces the likelihood of costly repairs.

Why Should a Professional Handle Your Air Line Upgrade?

Air line systems are complex, and their performance depends on precise installation, correct sizing, and expert configuration. Even small installation errors can lead to pressure loss, leaks, or long-term failure.

Professional installation provides:

- Accurate calculations of airflow, pressure, and distribution needs

- Safe installation practices that meet industrial safety standards

- Long-term reliability through proper technique and high-quality materials

Upgrades involve more than connecting pipes. They require strategic planning, pressure balancing, and equipment testing. Professionals ensure that every section of the new system functions correctly and integrates with existing compressors, dryers, and regulators.

Attempting the installation without professional assistance can create safety risks and operational inefficiencies. Expert guidance ensures a safe, efficient, and durable result.

When Upgrading Air Lines, Choose Confidence

If your facility is preparing for an air line upgrade, expert evaluation ensures the system meets current and future demands. Contact The Gas Connection for professional air line solutions that deliver long-lasting performance and reliability.